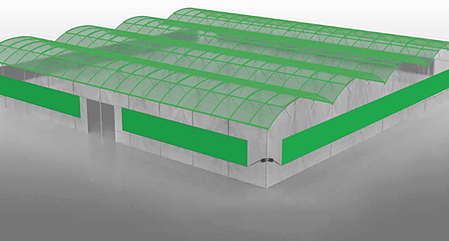

Agro United Engineering specialized in supplying and installing of greenhouses, and executing agriculture projects all over the world, either way delivered ready for use or in any other manner consistent with the requirements of the customer.

The project includes the establishment of engineering planning and construction of greenhouse and nursery building and equipment to take care of small plants also building facilities for packing in preparation for the crops to be shipped.

To achieve the best result in our project we also provide our customer’s all the advice and counseling they need all through project planning duration.

Agro United Engineering unique global-local approach to greenhouse TKP is based on the knowhow of our local agronomic experts around the globe.

It allows us to work hand in hand with you not only during the greenhouse project but afterward.

About Equipment We Supply:

Plastic film, double plastic layer, polycarbonate, cellular polycarbonate, metallic sheet, sandwich panel.

Plastic film, double plastic layer, polycarbonate, cellular polycarbonate, metallic sheet, sandwich panel.

Ventilation is one of the most important components in a successful greenhouse, specially in hot and humid tropical climate condition.

If there is no proper ventilation, greenhouses and their growing plants can become prone to problems. The main purposes of ventilation are to regulate the temperature, humidity and vapor pressure deficit to the optimal level, and to ensure movement of air and thus prevent build-up of plant pathogens (such as Botrytis cinerea) that prefer still air conditions. Ventilation also ensures a supply of fresh air for photosynthesis and plant respiration, and may enable important pollinators to access the greenhouse crop. Ventilation can be achieved via use of vents – often controlled automatically via a computer – and recirculation fans.

Optimal microclimate on crop level In modern greenhouses ventilation plays a vital role. Through circulation of air, heat distribution in the greenhouses is optimized, which enhances a uniform development of the crops. With the fan we supply, its offers the grower the opportunity to reduce the negative impacts, due to humidity, in a simple and energy efficient way. The vertical airflow results in an optimal uniform microclimate on plant level.

Why Chose this Fan:

Horizontal ventilation solutions for Greenhouses:

For greenhouses with large temperature/humidity variation, we have a horizontal circulation fan available for a more uniform indoor climate. This horizontal circulation fan mixes the air faster compared with the V-FloFan, but has less effect at root level. The V-FloFan and circulation fan are not suitable to use together.

Please, contact our Vostermans Ventilation team for technical details about the circulation 40 cm or 50 cm fan.

Features:

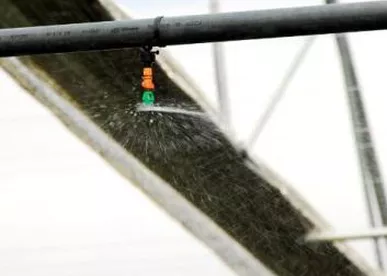

Air-fog, low pressure humidification.

Heating is one of the most valuable in the operation of greenhouses across the globe, especially in colder climates.Agro united engineering supply wide range of greenhouse heaterswith low operating cost:

GAS-FIRED UNIT HEATERS

Gas-fired unit heaters offer another option where infrared heating is not practical due to ceiling heights, clearances to combustibles or building use.

Features:

GAS HEATER

Gas heater are very efficient direct fired units. Due to their clean burning, all the heat can be sent directly into the greenhouse.

Features:

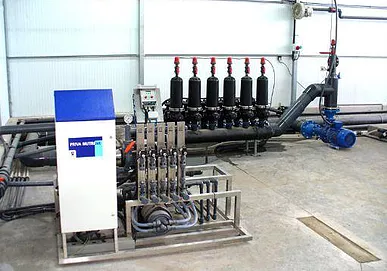

Agro Supply revolutionary software module that allows you to create your own custom controls for the computer, without any help from us . This means you can get even more out of your Climate controller and achieve even better growing results. Together with your crop consultant, you may come up with new ideas for maximizing crop production. In some cases, this requires adjustments to the control process that cannot be made with the available functionality. These control adjustments often require the input of additional system data that is corrected for multiple factors. To implement such changes, the new Climate controller we supply module includes the following features:

My Influences

Settings such as the ventilation setpoint are influenced by factors such as the radiation intensity (sunlight) and humidity level.

An influence adjusts a setpoint based on a measured value.

This allows the pre-programmed setting to be adjusted automatically based on changes in the ambient conditions. The Climate controller ‘standard’ influences can be used to fine-tune climate or irrigation control to your specific situation. our climate controller allows you to define your own custom influences that adjust graphical settings as you desire. With the My Influences feature, you are free to select which value should influence which setting. These custom influences can be based on standard readouts or even on pre-defined custom variables from the My Variables feature.

My Variables

Our controller software registers an enormous amount of data. The system displays readouts of all measured and calculated values. However, there may be situations where the available readouts or calculations do not meet your needs. This may be the case, for example, if you want to examine the correlations between readouts, or combine or edit certain values. It is also possible that your crop consultant asks you for information that is normally not available in the system, but can be determined from other data. The ‘My Variables’ feature allows you to create your own custom readouts that can be displayed in Synopta. There are various options for defining these custom variables:

Hooks, clips, sticky traps, nurseries trays

Sowing machines, germination chambers, trays carts, trays supports, cultivation trays.